Service data of SYMplus™

Last change: Apr 10, 2019

If you have problems with a PAL program, a Control simulator program or a Work plan, we can only get to the bottom of it, if we also know your tool data your presettings in addition.

Therefore, a function is built into the software that packs all relevant "service data" into a zip file.

Contents |

Save service data

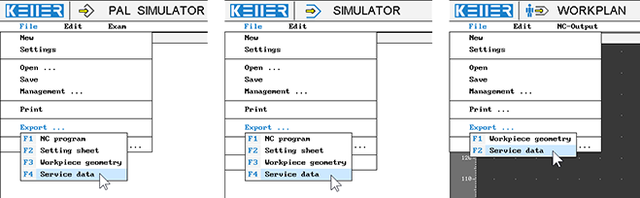

Load the concerning NC program or Work plan and then choose F1 File > F7 Export > F2 or F4 Service data.

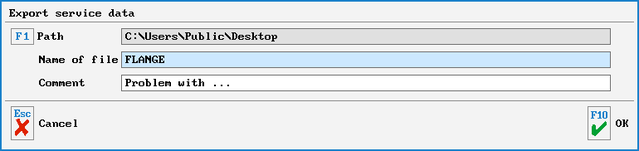

Via F1 path you can specify in which directory the 'zip-file' should be stored. If you do not select a path, the file is automatically saved to the root directory of the user data. Define a file name and add a short comment if necessary.

Additional data

There are no special "service data" in the operating modes 'G1 G2 G3' and 'Geometry' . Here the respective file can be analyzed individually. The contour exercises from G1 G2 G3 mode have the file extension CN1, geometry files have the file extension WS1.

If your problem is related to a particular 'postprocessor' , it's helpful to also send us the corresponding "parameter set". You will find this in the subfolder \ data \ param-sa in the user data, file extension PS1.

Faulty NC program

If an NC program created with SYMplus™ does not run on the machine, this can have different reasons:

You may have used a filename that the controller does not accept (spaces, special characters, Unicode, letters at all instead of just numbers, too many digits, ...). Some of these format errors may be caught by the postprocessor already, but not all.

Compare the header of the program created with SYMplus™ (which will usually contain the name or number of the program) with the header of a program that was written directly on the controller or that was previously transferred to the controller and started without problems. Then, as a precaution, adjust the header that is causing problems to the format of the other program.

Example: If program named "TEST123" workes fine, but "Exercise 1-2-3" does not work, try "EXE123".

However, if the error on the controller is only reported on the controller during simulation, make a note of the block and the error message displayed. Then try changing it so that the program will work without this error, and send us both programs (the original and the corrected one) along with the text of the error message.

Mail service data

Please email us the zip-file or the other relevant files together with the most accurate error description to support@cnc-keller.de.

When you send the email, please do not forget to include 'Name and address and - if available - 'Customer number' of the company, school or institute you are working for, so we can assign the support case immediately and can react quickly.