Crash in feed with milling tool

Last change: Jul 8, 2024

There are various reasons that can lead to a collision message in the feed. Of course, the software classifies it as a crash if the milling cutter moves into the protective zone of the clamping devices and collides with clamping jaws, parallel bars or, in the 3D simulation, possibly also with the table. Even if a non-cutting part (shank, holder) comes into contact* with material, this is a crash. As a rule, you are then offered the opportunity to move to the collision point so that you can identify the critical point in the programme or work step.

One crash that an inexperienced user often cannot explain is a G1 traversing unit in Z with an "end mill". This tool type does not cut over the centre in SYMplus™ as standard, so it cannot plunge vertically. Only tools of the "slot milling cutter" type can do this.

Picture:

Picture:

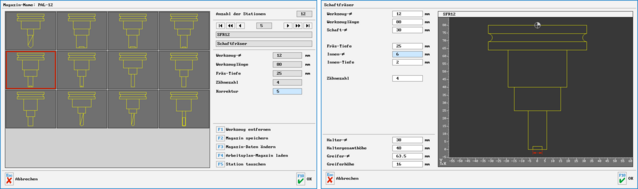

Left: Example magazine "PAL-12" with end mill SFR12 on station 5

Right: The same tool in F8 Set up > F2 Modify > ... > F3 Geometry

In the Geometry dialog of the slot milling cutter, this is visualised by the parameters "Internal Ø" and "Internal depth". Only if you set both to 0 and at the same time switch "Vertical cut-in" to "YES" under F2 Characteristics would an end mill also be able to plunge. But then it is easier to create it as a "slot milling cutter" right away.

- A contact is enough!

If this "first aid" does not help you in your case, please create a Service file and send it to support@cnc-keller.de with a brief description of the error!